Magnet drive pumps have long been the preferred option for handling hazardous or environmentally threatening liquids in safety critical applications in the chemical, petrochemical, pharmaceutical and processing industries.

This is because they do not leak. Magnet drive pumps combine an exceptionally long-term reliability with minimum maintenance requirements.

With the introduction of ever stricter environment legislation, product liability laws and health and safety regulations, more and more customers are demanding leak-free process environments.

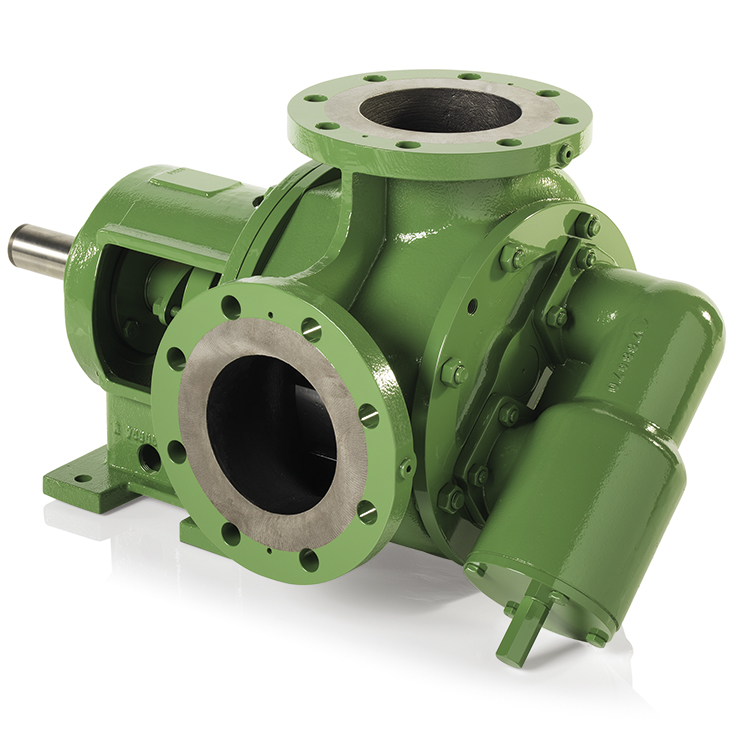

The principle of magnet pumps is very simple

A magnet drive pump allows the impeller to be driven without any physical contact with the motor.

The pump shaft and rotor are immersed in the process liquid and contained within a non-magnetic shroud through which the magnet power is transmitted.

There are two types of sealless magnetically drive pump designed for different applications

The first type of magnetically driven pumps uses powerful "Rare Earth Magnets", mounted within the rotor to provide an inner magnetic ring and direct attraction spins the impeller at the same speed as the outer magnetic ring coupled to the prime mover. Though extremely efficient, these synchronous drive pumps are limited to a maximum temperature of 260ºC.

The second type of magnetic drive uses the "Torque Ring" drive coupling, in which the torque ring is drawn after the outer magnet ring at a slightly slower speed. The design is ideally suited to high temperature operations; the Torque Ring pumps can operate uncooled with liquids up to 450ºC.